OCXO and OCSO

- Products

- Browse by Products

- OCXO and OCSO

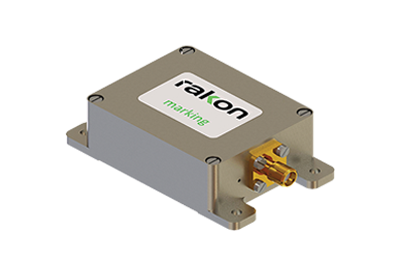

Rakon has been at the forefront of OCXO technology for several decades, offering an extensive selection of products that includes highly stable miniature IC-OCXOs and 24-hour holdover PPS disciplined OCXOs tailored for telecom and data centre needs, as well as radiation-hardened OCXOs and ultra-low phase noise OCXOs/OCSOs designed for space and defence applications. In addition, our ultra-stable OCXOs (USOs) boast an ADEV of up to 6 x 10-14, making them ideal for instrumentation and ground stations.

OCXO and OCSO

Frequently Asked Questions

What's the difference between an OCXO vs. a TCXO?

The internal temperature of an OCXO is regulated at a set point temperature higher than the maximum operating temperature, while the temperature of a TCXO is not regulated. Therefore the frequency variations over temperature that occur in an OCXO are significantly less than that of a TCXO over the operating temperature range of the product. The temperature compensation in an OCXO can generally achieve a much higher level of frequency stability compared with a TCXO. Consequently, the heating required to maintain the crystal’s temperature in an OCXO also means that the power consumption is higher than that of a TCXO.

What are key applications of IC-OCXOs?

IC-OCXOs deliver excellent frequency stability over temperature (FvT), long term stability, phase noise performance, low component count (providing a higher reliability) and low power consumption. These key features together make them an ideal choice for Stratum 3E, PTP-enabled ethernet switches & routers, cable modem CMTS and remote PHYs, base stations, 5G RRH, small cells and microwave transmission systems.

What is the performance difference between an AT and a SC cut crystal? Which cut is better for OCXO applications?

The AT cut crystal is the most widely used of all the crystal cuts in the frequency control market. This is due to the inflection point of 25°C and the symmetry of the frequency versus temperature (FvT) characteristics. The SC cut crystal provides a higher long-term stability and hysteresis performance compared to the AT cut. The inflection point (which is the temperature where the crystal is most stable) of an SC cut is around 93°C, compared to 25°C for an AT cut. This characteristic makes the SC cut better suited to OCXO applications.

What are the IT, BT and Y-cut performance characteristics?

The IT cut is a modified SC cut to reduce the B-mode frequency effects. The stress compensation is slightly less and the inflection point temperature typically moves several degrees higher. The BT cut is similar to the AT cut and can run at higher frequencies. The temperature stability is however not as stable. Lastly, Y-cuts have a large frequency vs temperature slope (~80 ppm/°C) making them ideal for temperature sensing applications.